INTRODUCING

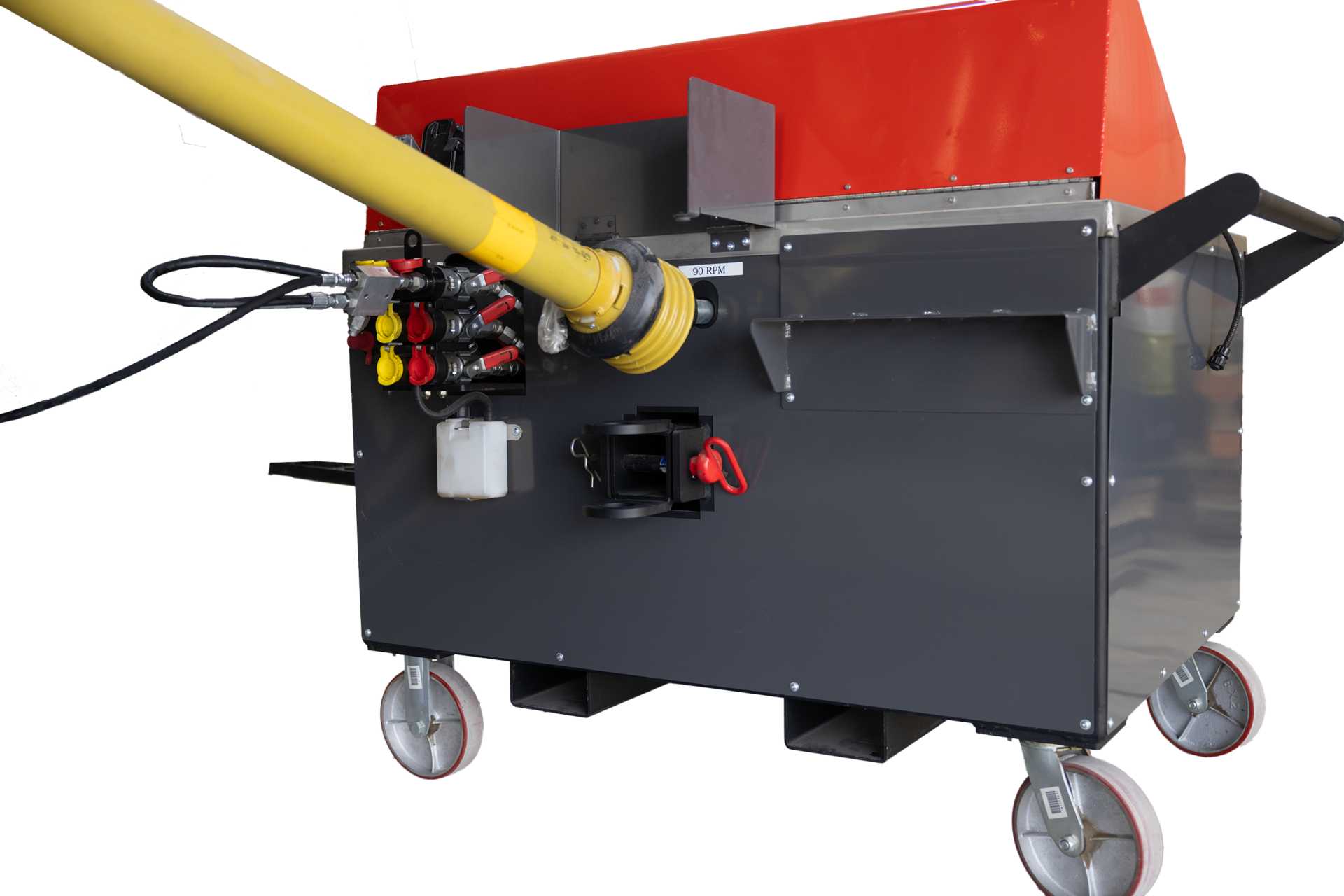

A hydraulic PTO system that eliminates the need for a tractor.

All you need is the machine itself

no extra equipment required!

FEATURES

Convenient

Streamlines operations

Safer

Enhances safety with easy controls

Space Saving

Compact, freeing up workspace

Cost Effective

Quiet

TECH SPECS

ELECTRICAL

ISObus connectors with monitor mount

Two G31 deep cycle batteries

20 amp smart battery charger

Two 7 pin trailer plugs with switches

One 3 pin 12V auxiliary

Two USB charging outlets

Voltage gauge

MECHANICAL

2 PTO shafts with reverse function

Variable speed PTO

1-225 rpm

5 to 225 RPM

Wireless remote control

HYDRAULICS

3 Valves with breakaway couplers with 2 with cycle spools, 1 with a motor

spool

2 flow control valves

TESTIOMONIALS

We have used the Tech Trolley for about two years, and my favorite thing about it is that we no longer have to run a tractor every time we need to operate an implement. This helps us save tractor hours while also keeping the air in our shop much cleaner. As a result, our team stays healthier and happier, and the reduced noise level compared to running an engine makes for a better working environment. We also frequently use the ISO function. When hooking up a planter, baler, or potato harvester with an ISO display screen, we can control its functions and update software without needing to connect to a tractor. This is a huge time saver when updating software on a machine, checking acres on a used planter or troubleshooting a sensor on an implement. Additionally, for potato equipment, the Tech Trolley greatly simplifies and enhances the safety of the belted chain installation and removal process. The adjustable PTO speed is an incredibly useful tool in these situations. These are just a few of the reasons we appreciate the Tech Trolley, and we would never want to be without it in our service department.

We here at Hepson Equipment purchased a Tech Trolly one year ago. We had explored all options to test equipment in our shop and this seemed to be the best solution for us. In the last year we have use it to test various equipment , Claas balers, Penta mix wagons, Salford equipment, Bunning Spreaders, Kubota implements and so much more. It is used to test for repair issues, predelivery inspections and general running condition of equipment. All our technicians find it is easy to work with and very handy around the shop. Great product, Thanks AllAg for your support!